Understanding Nitrogen Regulators

Nitrogen regulators are essential devices designed to control the flow and pressure of nitrogen gas from a cylinder to a specific application. Whether used in food and beverage processes, industrial applications, or HVAC systems, these regulators play a critical role in ensuring safety, efficiency, and proper functioning. Understanding the nuances of nitrogen regulators can be vital for businesses and technicians alike. This guide serves to provide an in-depth look at nitrogen regulators, their applications, features, and installation considerations, helping you make informed decisions.

For in-depth information on various models, visit the nitrogen regulator section at Alpha Weld.

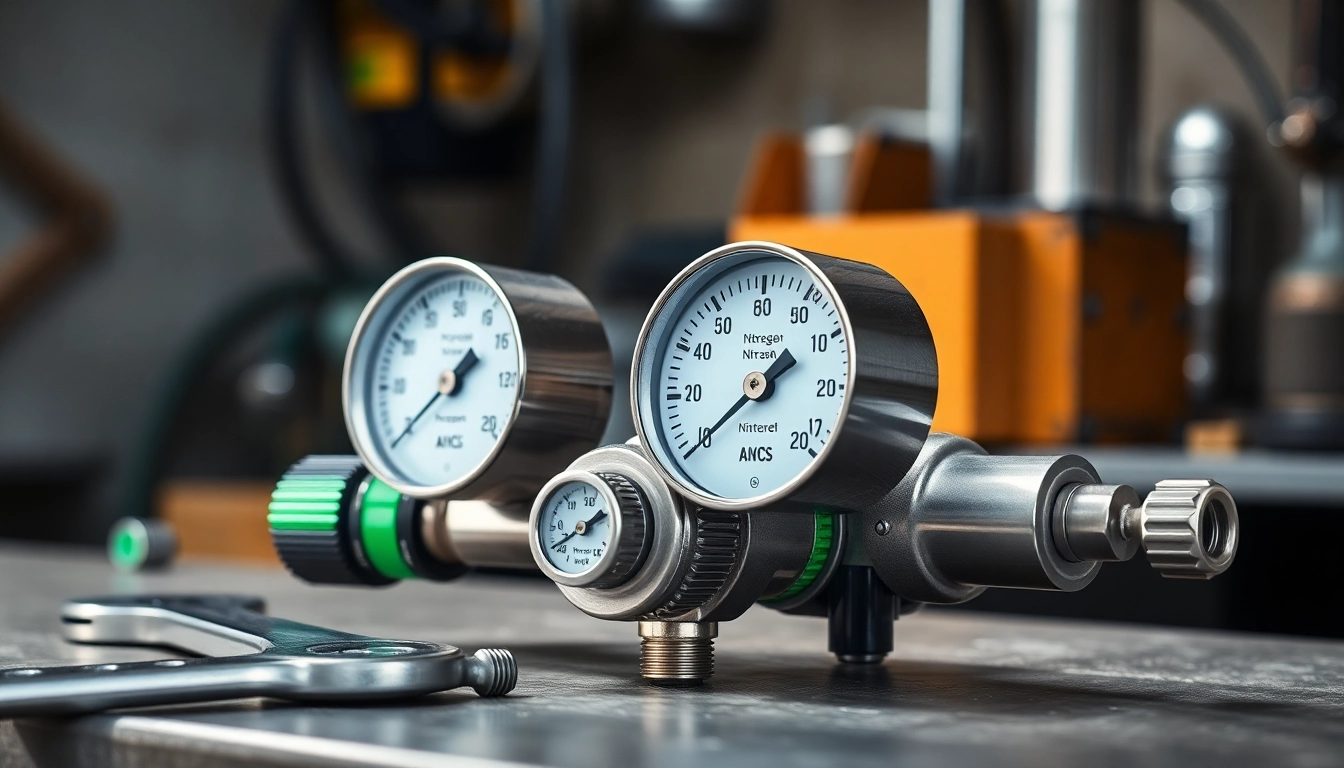

What is a Nitrogen Regulator?

A nitrogen regulator is a device that reduces the high pressure of nitrogen gas from storage tanks or cylinders to a lower, manageable pressure. This reduction is critical for safe handling and use in various applications, from purging tanks and pressure testing to beverage dispensing and HVAC systems. A well-designed regulator ensures that nitrogen is dispensed at a consistent and controlled pressure, preventing equipment damage and enhancing operational efficiency.

How Nitrogen Regulators Function

The functionality of nitrogen regulators revolves around a few key components: the inlet connection, pressure reducing mechanism, and outlet connection.

The process starts when nitrogen gas enters the regulator through the inlet connection (commonly a CGA580 connection). The regulator then employs a diaphragm that reacts to pressure changes, allowing a steady flow of gas through its outlet.

As the device maintains output pressure, it balances the difference between the inlet pressure and the outlet pressure, delivering a steady flow. This is particularly useful in applications needing precise gas pressure, as any spike or drop could render the operation ineffective or hazardous.

Common Applications for Nitrogen Regulators

Nitrogen regulators find extensive use in various fields including:

- Food and Beverage: Nitrogen gas is commonly used in the beverage industry for dispensing beers and ensuring the freshness of foods.

- HVAC Systems: Nitrogen is used to pressure test HVAC systems, enabling technicians to identify leaks and ensure system integrity.

- Welding and Metal Fabrication: Nitrogen is used for shielding gases to protect welds from oxidation during welding.

- Laboratories: Nitrogen serves as a blanketing gas in lab environments to protect sensitive chemicals from reacting with moisture in the air.

Types of Nitrogen Regulators

When selecting a nitrogen regulator, it’s essential to understand the different types available. Each type is tailored to specific applications and user needs.

Single vs. Dual Outlet Nitrogen Regulators

Nitrogen regulators can be categorized based on the number of outlets they feature:

- Single Outlet Regulators: These are designed to provide nitrogen gas to a single application point. They are simpler and often more affordable, making them suitable for basic applications.

- Dual Outlet Regulators: These offer two separate outlets, allowing users to operate two applications simultaneously without needing to switch connections. Dual outlet regulators are often favored in commercial settings where multiple processes utilize nitrogen.

Adjustable vs. Preset Nitrogen Regulators

Another classification of nitrogen regulators is based on pressure adjustment capabilities:

- Adjustable Regulators: These devices allow users to customize the output pressure to meet specific operational requirements, making them versatile for various applications.

- Preset Regulators: These regulators come calibrated at a specific output pressure. They are straightforward and eliminate the risk of accidental pressure adjustments, suitable for applications requiring consistent pressure.

Choosing High-Pressure vs. Low-Pressure Regulators

It’s crucial to choose the right type of nitrogen regulator based on pressure requirements:

- High-Pressure Regulators: These are capable of handling pressures above 500 PSI. They are typically used for industrial applications that require high gas flow rates.

- Low-Pressure Regulators: These regulators operate typically below 500 PSI and are suitable for applications such as beverage dispensing and laboratory uses.

Key Features to Look For

When selecting a nitrogen regulator, consider the following key features to ensure it meets your requirements:

Pressure Ratings and Flow Capacities

Understanding the pressure ratings and flow capacities is essential to match the regulator with your application. Most nitrogen regulators will specify their maximum inlet and outlet pressures, typically indicated in PSI (pounds per square inch) or BAR. Additionally, flow rates are crucial as they determine how quickly the nitrogen can be delivered to the application. Assess your needs carefully to ensure the regulator can meet the operational demand without failure.

Material Durability and Construction

The construction material plays a pivotal role in the longevity and safety of nitrogen regulators. Common materials include brass, stainless steel, and aluminum. Brass is often used for its strength and resistance to corrosion, while stainless steel provides enhanced durability in harsh environments. Selecting a regulator made of quality materials ensures robust performance and reduces the risk of gas leaks.

Gauge Types and Their Importance

Most nitrogen regulators come equipped with gauges that allow users to monitor pressure levels. There are generally two types of gauges:

- Tank Pressure Gauges: These indicate the pressure inside the nitrogen cylinder, helping users gauge when a refill is needed.

- Output Pressure Gauges: These display the pressure being delivered to the application, allowing adjustments as required. Monitoring output is crucial for applications sensitive to pressure variations.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the effective operation of nitrogen regulators. Here are some best practices to follow:

Step-by-Step Installation of a Nitrogen Regulator

- Gather Necessary Tools: Ensure you have the appropriate tools, including adjustable wrenches and Teflon tape.

- Check Cylinder Valve: Before installation, inspect the nitrogen cylinder’s valve for damages or leaks.

- Attach the Regulator: Carefully connect the regulator to the cylinder valve. Use Teflon tape on threads to ensure a leak-free connection, tightening it securely without applying excessive force.

- Open the Cylinder Valve: Gradually open the cylinder valve to allow nitrogen flow, observing the regulator gauges for any irregularities.

- Set Output Pressure: Adjust the output pressure based on your operational needs using the regulator’s adjustment knob.

Regular Maintenance Practices

Regular maintenance is vital for optimal performance and longevity of nitrogen regulators:

- Visual Inspections: Routinely inspect for signs of wear, corrosion, or leaks.

- Gauge Calibration: Periodically check the gauges for accuracy, recalibrating if necessary.

- Replace Seals and Diaphragms: Over time, seals and diaphragms may wear out; replace them to maintain effective operation.

- Testing for Leaks: Use a soap solution around connection points to detect leaks non-destructively.

Troubleshooting Common Issues

Even well-maintained nitrogen regulators may occasionally encounter issues. Here are some common problems and their potential solutions:

- Inconsistent Pressure: If the output pressure is fluctuating, check for leaks in the connections and ensure the diaphragm is functioning properly.

- Gauge Failure: If gauges are reading inaccurately, they may need recalibration or replacement. Check for blockages in the gauge line.

- Gas Flow Issues: A flow obstruction might necessitate inspecting the outlet connection for debris or blockages.

Comparing Popular Nitrogen Regulators

With numerous options available, choosing the right nitrogen regulator can be overwhelming. Here, we outline critical points to consider when comparing popular models:

Top Brands and Their Offerings

Some of the leading brands in nitrogen regulators include:

- Uniweld: Known for its robust and durable models suitable for industrial applications.

- Victor: Offers a range of regulators with advanced pressure control features for precision applications.

- Airgas: Provides a wide selection of regulators tailored for both high and low-pressure needs.

Price Comparison Guide

The price of nitrogen regulators can vary considerably based on brand, features, and specifications. Budget models might start around $20, while high-end models can exceed $150. Evaluate your application needs against price to find a suitable balance.

Customer Reviews and What to Consider

When exploring options, customer feedback provides invaluable insights. Look for reviews regarding:

- Reliability: Does it perform consistently under various conditions?

- Ease of Use: Are the setup and adjustments straightforward?

- Durability: How does the regulator hold up under regular use?

Conclusion

Understanding nitrogen regulators is crucial for anyone involved in industries that utilize nitrogen gas. From knowing the different types and features to proper installation and maintenance, having a robust knowledge base can significantly impact operational efficiency and safety. Always source regulators that meet industry standards, and consider how your specific application drives your choice of regulator type.